Canadian Centre for Advanced Material Manufacturing

National Research Council l Mississauga Facility

The National Research Council’s (NRC) Canadian Centre for Advanced Material Manufacturing research facility involved the construction of a new addition, spanning a total area of 2,597 square meters (27,954 square feet). This state-of-the-art facility was developed to enhance the capabilities of the NRC in Mississauga, Canada.

Meeting NRC Quality Standards: The NRC has rigorous quality standards for its facilities to ensure they can support high-level scientific research. Achieving these standards required precise engineering, high-quality materials, and adherence to strict specifications.

Tight Schedule & Trade Coordination: Pomerleau, the general contractor, imposed a tight construction schedule, necessitating efficient coordination among various trades. Timely delivery was critical to meet the NRC’s occupancy turnover requirements.

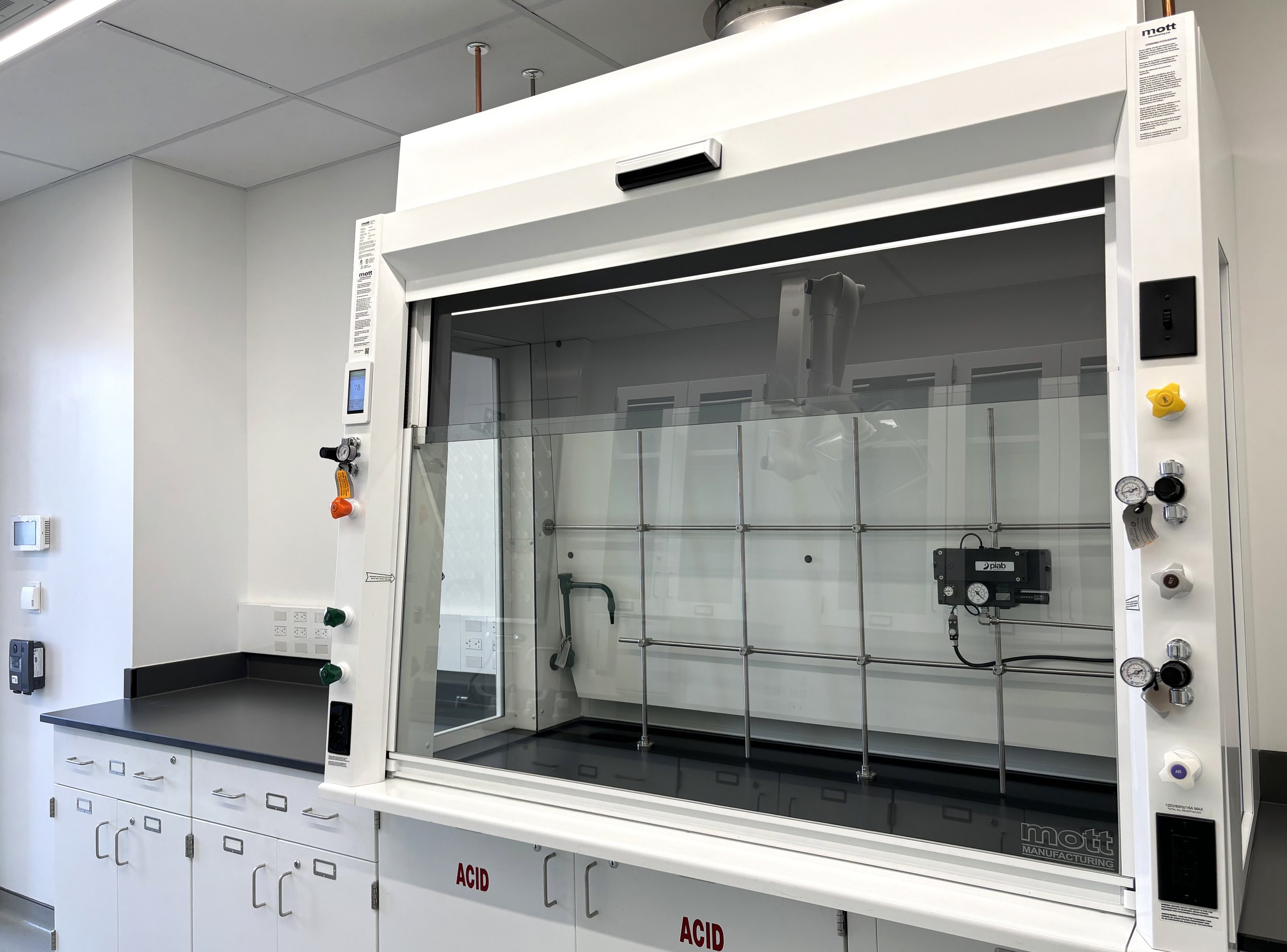

Complexity of Specialized Installations: The facility required the installation of sophisticated laboratory equipment and systems, including Optima™ fume hoods with electronic hydraulic lift countertops and media grid ceiling support structures. This complexity demanded seamless integration and expert handling.

Collaborative Efforts: Mott and mottLAB played a crucial role in the successful completion of the NRC Mississauga project. Their collaboration with Pomerleau was instrumental in ensuring the project met its deadlines and quality benchmarks. Mott and mottLAB’s expertise in providing specialized laboratory equipment and systems was pivotal in meeting the NRC’s exacting standards.

Flexible Lab Design: A core feature of the project is its focus on flexible lab design. The lab spaces are strategically configured with modularity at the forefront, enabling easy horizontal expansion. Demountable walls provide the flexibility for seamless lab growth, while a custom-designed lab solution incorporates integrated wall systems and overhead service carriers, supporting plug-and-play reconfiguration of adaptable, mobile lab furniture such as Optima™ benches and various tables. Ceiling-mounted service panels allow for full reconfiguration of the lab layout without interrupting electrical or plumbing systems, ensuring the space can evolve alongside changing research requirements.

The NRC Mississauga project stands as a testament to successful collaboration and meticulous project management. Despite the challenges posed by stringent quality standards and tight schedules, the combined efforts of Pomerleau, Canada First, Mott, and mottLAB ensured the project was completed on time and to the highest standards. This project exemplifies the potential for excellence through teamwork and specialized expertise, setting a new benchmark for future scientific facility constructions.

-

Mississauga, Ontario, Canada

-

The Canada FIRST Joint Venture (a collaboration between HOK, Architecture49 and WSP), Pomerleau, Mott Manufacturing

-

Overlay casework, overhead ceiling service panels, acid cabinets, insulated solvent cabinets, pump cabinets, stainless steel work surfaces, cylinder storage racks, vented cabinets, peg boards

Optima™ Benches: single and double sided, standard and custom heights, custom circuits (3-4), EdgeWave LED task lights

Various Tables: Optima™ adjustable height, welded height adjustable, custom double sided mobile tables with drawers on both sides, mobile adjustable height welded tables

Laboratory Media Ceiling System: this project showcased the integration of our large-scale Ballroom HPC-ASI-LMC Series Laboratory Media Ceiling, offering a flexible and modular approach for mounting and distributing ceiling utility services. The design accommodates traditional ceiling elements, including service panel distribution hubs, drop-down umbilical service drops, local extraction devices, air supply systems, lighting, fire protection systems, suspended shelving/casework, interstitial soffit isolation panels, and demountable full-view wall partitions with integrated entry/exit doors.

RFV2™ fume hoods with phenolic liners, stainless steel distillation racks, pass-throughs, pre-wired custom electrical, pre-plumbed with pressure regulators, ionizing bar, sash enclosures, VAV alarm, and PIAB air driven vacuum pump

RFV2™ stainless steel fume hoods with stainless steel seamless liners, stainless steel distillation racks, pre-wired custom electrical, sash enclosures, VAV alarm, and PIAB air driven vacuum pump, pre-plumbed with pressure regulators on AIR, ARG, AD NIT, including chilled water with insulated water supply and return chilled plumbing lines, pass throughs, deionizing bar

NovaGuard™ fume hoods with static dissipative phenolic liner and baffles, side viewing windows, stainless steel distillation racks, sash enclosures, VAV alarm, and PIAB air driven vacuum pump, pre-wired, pre-plumbed with chilled water with insulated water supply and return chilled plumbing lines

Optima™ painted steel fume hoods with FRP liners, static dissipative phenolic liner and baffles, stainless steel distillation racks, sash enclosures, VAV alarm, and PIAB air driven vacuum pump, deionizing bar, custom electrical, pre-plumbed with pressure regulators on AIR, ARG, AD NIT, including chilled water with insulated water supply and return chilled plumbing lines

Optima™ stainless steel fume hoods with stainless steel liners, static dissipative phenolic liner and baffles, stainless steel distillation racks, side viewing windows, sash enclosures, VAV alarm, and PIAB air driven vacuum pump, deionizing bar, custom electrical, pre-plumbed with pressure regulators on AIR. ARG, NIT, including chilled water with insulated water supply and return chilled plumbing lines

Hydrofluoric Acid fume hoods with PVC liner, baffles and worksurface, stainless steel distillation racks, sash enclosures, and more (Teflon coating on all stainless steel parts), custom electrical, CAV alarm, pre-plumbed

Perchloric acid painted steel fume hoods with stainless steel seamless liner with integral top and integral drain trough, stainless steel distillation racks, sash enclosure box, custom electrical, CAV alarm

Many of the fume hoods on this project included automatic Sash Operators ASO2 Plus